T.C.P

Trivalent Chromium Passivation Process (T.C.P Surtec-650) as per MIL-DTL-5541F Type II Class 3

CLASS 3: Trivalent Chromium Passivation coatings are intended as a corrosion preventive film from electrical and electronic applications where low resistance contacts are required.

Hexavalent chromium free Passivation for aluminum, magnesium & casted aluminum alloys. suitable as post-treatment of anodic coatings (Anodizing) and conversion coating of magnesium alloys, excellent bare corrosion protection comparable to hexavalent passivation. It produces an iridescent, faintly blue to tan and visible layer, Complies with LN 9368-3 ID-number 1108 meets or exceeds MIL-DTL-81706B and MIL-DTL-5541F for bare corrosion (336 hours in NSS. per ASTM B-117, respectively, DIN EN ISO 9227) low contact resistance: < 5000 µOhm per square inch per MIL-DTL-81706B, heat resistant inorganic passivation layer (see “hints”) applied for US-patent: 6,375,726; 6,511,532; Product Sample

6,521,029; 6,527,841.

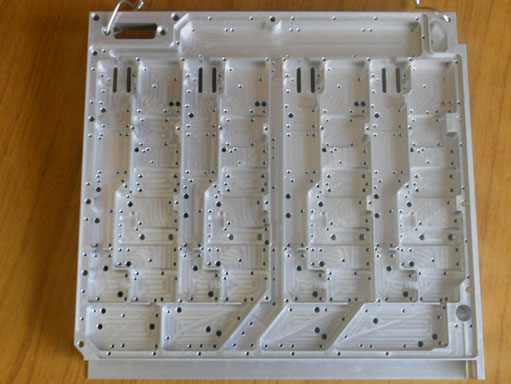

Trivalent Chromium Passivation (T.C.P)

Untreated12 h NSS

SurTec650 – chromitAL336hNSS